Damage Analysis and Material Consulting

Thanks to our versatile analysis methods, we can advise you both in the event of damage and as a preventative measure to avoid damage, including the associated material expertise.

The aim of our damage analysis is to identify the cause of the defect. This involves combining the technical operating conditions and the results of laboratory tests on the failed component for assessment. Competent and experienced engineers from the fields of materials testing, chemical analysis and cleanliness analysis are available to you for this purpose.

Plastics, metallic parts/components and chemical analysis

The entire range of testing options of the physical and chemical materials laboratory, measurement technology and cleanliness analysis are available for laboratory testing. Together with the know-how of our engineers and specialists, you can derive damage prevention measures from the test reports and avoid failures. Benefit from our experience with a wide range of materials - we will be happy to advise you.

As the mechanical properties of plastics in particular are much more strongly influenced by climate and time than those of metallic materials, special attention is paid to these factors.

To prevent damage, we will inform you about the selection and areas of application of the materials, from chemical resistance and mechanical wear resistance to corrosion resistance.

The analysis methods are suitable for a wide range of materials such as plastic, metal, concrete, paper, insulating material, coatings, etc.

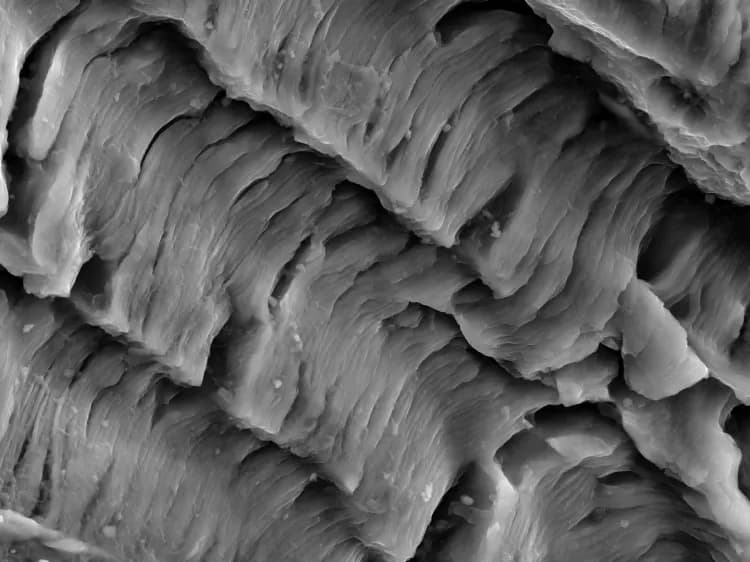

Scanning electron microscopy

- Visualization and assessment of the surface topography of fracture surfaces, signs of corrosion and wear

- Determination of the chem. Elements of residues, deposits and inclusions using EDX analysis

- Examination of conductive and non-conductive samples (e.g. plastics)